As the country vigorously develops renewable new energy, with the advantages of clean and renewable energy, wind power has become one of the fastest growing energy sources and one of the most economical power generation solutions.

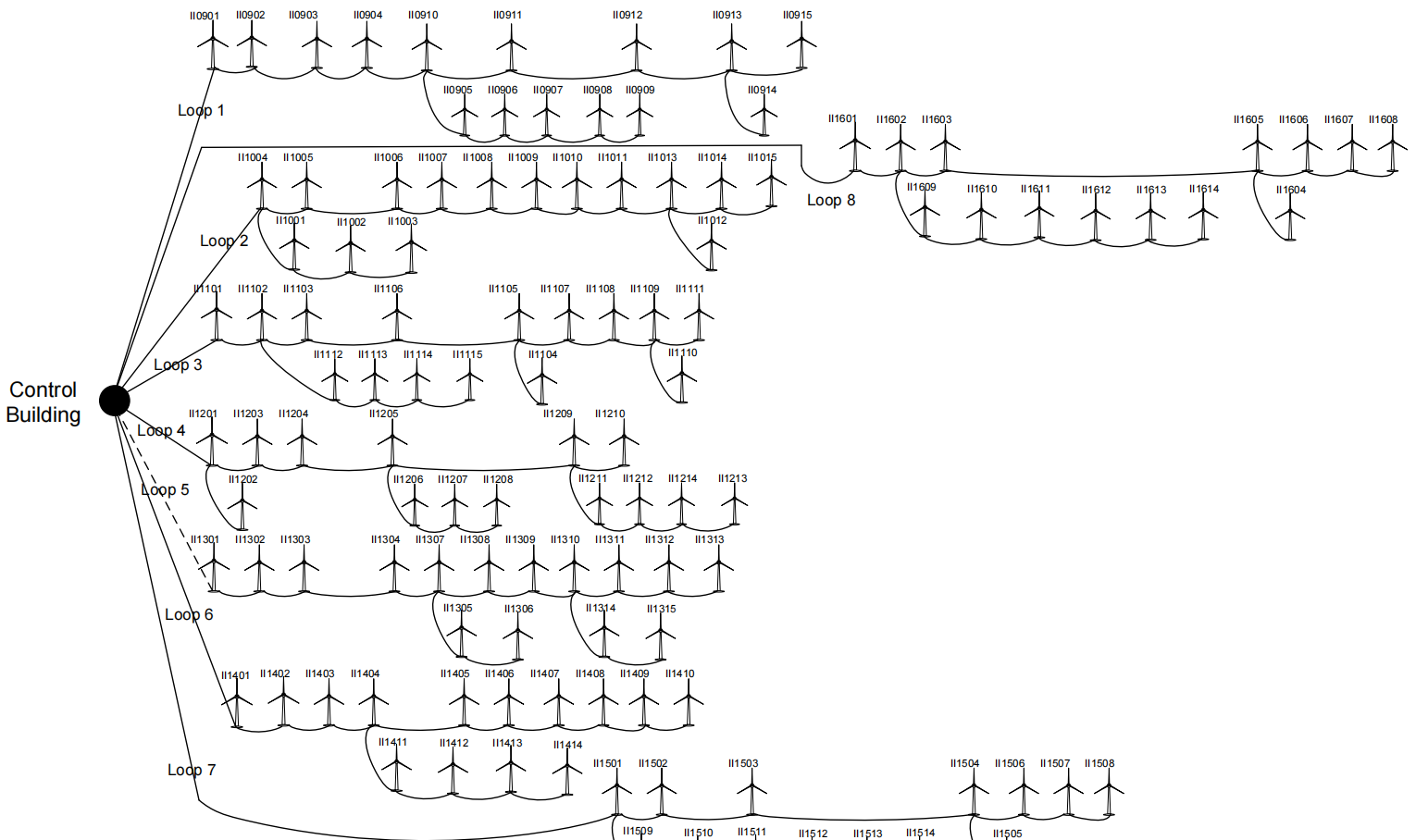

In order to continuously improve wind power generation and better control the wind turbines, each wind turbine will have some monitoring data and monitoring videos that need to be sent back to the central control room of the substation. Due to the scattered and wide distribution of wind turbines in wind power plants, optical fibers are generally used to transmit the data collected by the wind turbines.

Today, Fibertone Technology will teach you how to build the optical transmission network of the wind power plant. The data collected by each fan is generally in the form of Ethernet electrical signals, so we must first convert these Ethernet electrical signals into optical signals. If the number of wind turbines is small, a fiber optic transceiver can be used to convert the Ethernet electrical signal into an optical signal and then directly transmit it back to the central control room of the substation.

When there are a large number of fans and they are distributed in groups, if the optical fiber transceiver is directly connected to the central control room at this time, then a large number of optical fibers need to be laid, which will not only increase the cost, but also easily cause line confusion, which will bring extreme maintenance to the maintenance. big trouble. Therefore, the correct method is to use the fiber billion industrial switches to form a ring network.

Fiberlink industrial-grade switches support multiple electrical ports and multiple optical ports. The electrical port can intervene in the local fan business, and the optical port is generally used to interconnect the fans at the adjacent site to form a fiber ring network. It not only provides abundant interfaces, but also forms ring network protection, which improves the stability of fan data transmission.

Fiber billion industrial Ethernet switches, products comply with FCC, CE, ROHS standards. Support photoelectric interface, support console port; support Ethernet Layer 2 protocol required by industrial sites to ensure the stability of communication network; this series of switches adopts low power consumption, fanless design to ensure no noise interference, and supports -40~85 ℃ working temperature and good EMC electromagnetic compatibility performance, ensure stable work in harsh industrial environments, and provide a safe and reliable solution for wind power plants to set up a fast and stable network terminal access network. The protective-grade housing and LED indicators make it a plug-and-play industrial-grade device, providing a reliable and convenient solution for users' Ethernet device networking.